| Description : |

|---|

| Group : Production lines |

1. corn blender :

- Capacity of 400 kg.

- Made of food Chrome 304 St.

- Equipped with a standard discharge hole.

- An opening to indicate the level of materials inside it.

- Equipped with mechanical protection to prevent the worker's hand from entering the mixer (metal mesh).

- Equipped with electrical protection to protect the worker's hand during cleaning.

- Equipped with a mechanism for withdrawing metal impurities if found inside the atom.

- The engine is a Turkish GAMAK brand with a capacity of 3 horsepower.

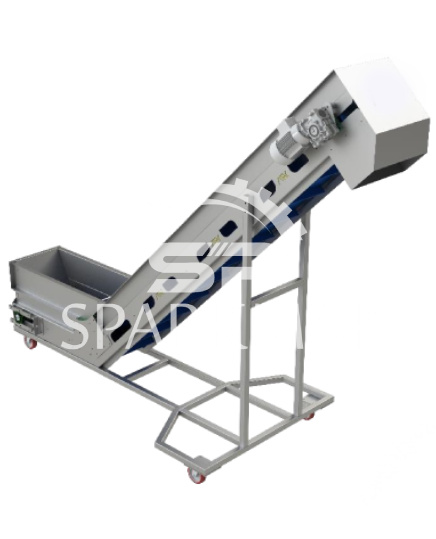

2-Helix conveyor to extruder :

- It consists of a 150 kg bucket made of Chrome.

- Equipped with a bottom hole for cleaning.

- It works on feeding materials to the extruder automatically.

- Equipped with mechanical protection to prevent the worker's hand from entering the mesh Basin.

- The engine is a Turkish gamak engine with a capacity of 1.5 hp.

3-vertical extruder for blasting and forming with automatic feeding device :

- Production capacity is 175 kg / hour.

- The gearbox is made of the finest metals that withstand the pressure of working hours.

- Bearings and bearings are manufactured by the German SKF brand.

- The snail is made of the finest metals and processed by the latest vacuum furnaces.

- The aquarium is equipped with a Turkish GAMAK engine.

- Main engine (compressor) with a capacity of 50 hp brandgamak Turk 900 RPM/ d.

- The speed of the extruder Motors is controlled electronically by inverter.

- The length of the grain is controlled by controlling the speed of the knife electronically (inverter).

- Production capacity 175 kg / h American model the extruder is automatically fed.

- All extruder operations are controlled by a main control panel made of Chrome and independent of the extruder body with ventilation filters and fans to cool the board.

4-conveyor belt to the oven :

There are two types of vectors as desired :

A - a chrome conveyor belt with a 1 hp engine.

B-a crystal pneumatic conveyor with a transparent hose.

5. oven :

- Equipped with a unique mechanism where various energy sources can be used according to the customer's desire at the same time.

- The length of the oven is 6 meters, the width is 90 cm.

- Saves more than 80% of energy due to its high technology.

- Equipped with two air motors for drying inside the oven to refine hot air to save energy (economical) in electricity, diesel or gas.

- The oven is fully encapsulated and insulated in an engineering way from stainless steel.

- Its functions are controlled through the power panel.

6-spiced roller :

- It is a horizontal cylinder made of Chrome 304st.

- The speed of the seasoning is controlled electronically (inverter).

- The cylinder is ribbed in a way that prevents flavors from clumping for the best result.

- The flavor is pumped and the pumping speed is controlled electronically (inverter).

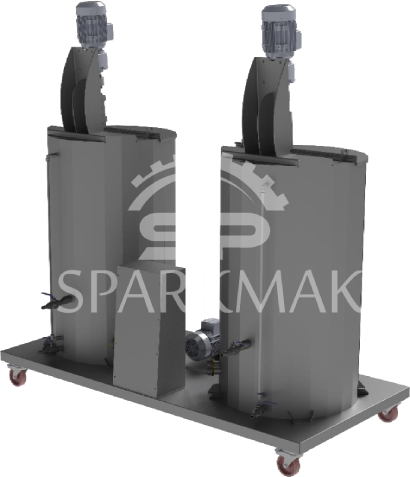

7-Oil and flavor mixers :

- Made of food grade chrome 304.

- The capacity of the mixer is 200 liters.

- Double jacket is made for heating by hot water.

- Flavor mixers and pump are connected on one table.

- The engine type is Turkish GAMAK + gearbox.

- Equipped with its own electrical panel.

- The pump type is food Chrome.

- The pump speed is controlled electronically.