| Description : |

|---|

|

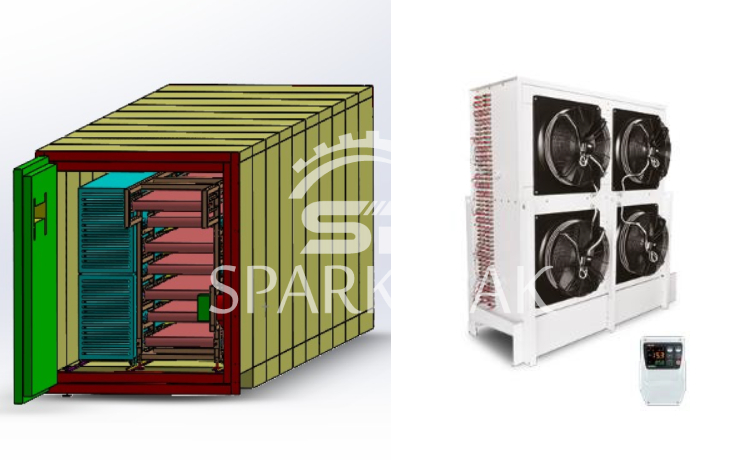

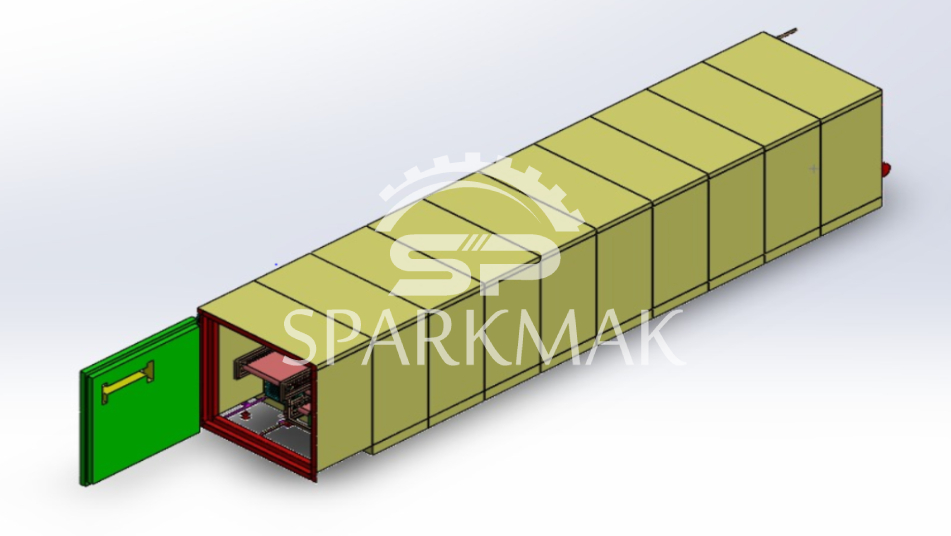

Technical specifications : The tunnel consists of two stages, a preliminary cooling stage and a quick freezing stage ( shock), and the two stages operate with a conveyor belt system separated by a distance of 20cm, where the product is graduated from one level to another until it comes out in the required form |

| Group : Single Machinery |

Specifications of the initial cooling stage :

* Cooling a product from a temperature of 40 degrees up to 15 degrees Celsius

• 304 stainless steel conveyor belt

* External structure made of coated steel insulated with polyurethane 20 cm thick

* Refrigerant gas: R-404A

* Device power input (V / Ph / Hz): 400 V / 3 Ph / 50 Hz

* Compressor type: PISTON ONE STAGE

* Compressor origin: Italian

Specifications of the quick-freezing tunnel ( stun ) :

* Cool the product to a temperature of up to minus 18 degrees.

* Refrigerant gas: R-404A

* Device power input (V / Ph / Hz): 400 V / 3 Ph / 50 Hz

* Compressor type: PISTON DOUBLE STAGE

* Compressor origin: Italian

• High and low pressure protection switch (combined pressure switch)

* Vibration sensors in the compressor Inlet and outlet line

* Solenoid valve in the liquid line

* Optical glass with humidity indicator

* High capacity dehumidifiers (drier)

* Liquid tank

• Full electrical panel

• Oil separator, oil filter, check valve

* DYB (oil pressure)

* Voltage 380V, 50Hz

* The air temperature inside the chamber is -35 degrees Celsius

* External structure made of coated steel insulated with polyurethane 20 cm thick

* Food conveyor belt.

* Electrical control is carried out using control inverters and a temperature display device

• All electrical parts used are European brand.